Achieving optimal energy-saving measures

Kinden offers plans to renovate facility systems with facility lifecycles in mind after examining issues of existing facilities. As part of this, we also suggest saving energy utilizing an integrated facility diagnostic program and strive to develop an environment in which to promote comfortable living.

Approach

Feature01

Energy conservation diagnosis and equipment diagnosis system

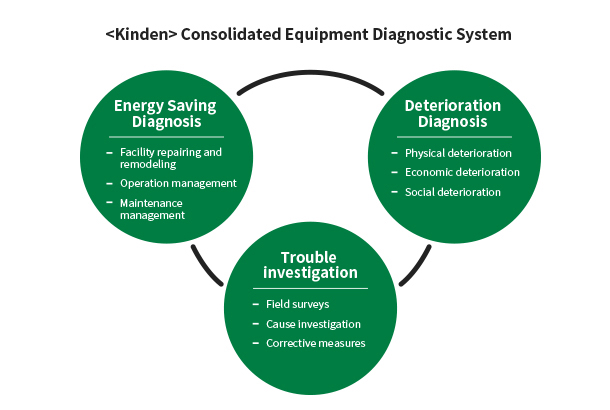

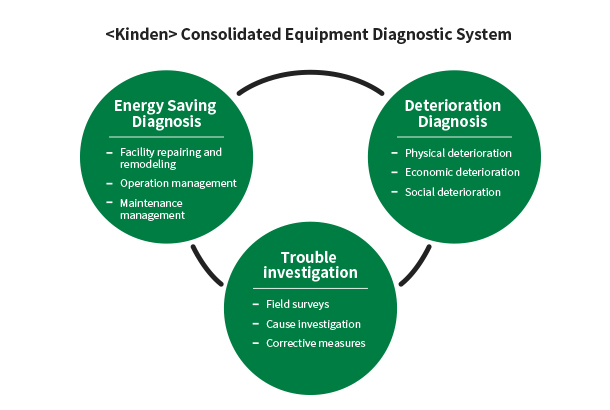

Kinden provides a complete range of integrated services — from energy conservation evaluation and diagnosis, equipment evaluation and diagnosis and trouble investigation to analysis and evaluation of survey results, improvement proposals, improvement design, implementation and inspection. Kinden’s Comprehensive Equipment Diagnostic System, for instance, provides an overall, integrated assessment of equipment energy conservation capabilities and deterioration renewal. It is a total system designed to achieve optimal energy conservation in the interests of streamlining business efficiency and operations.

Feature02

Comprehensive Equipment Diagnostic Program

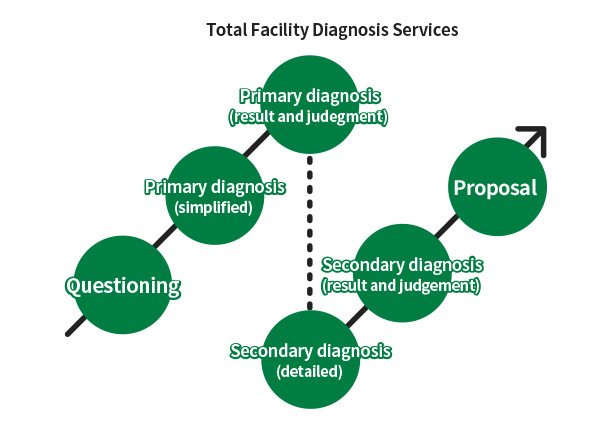

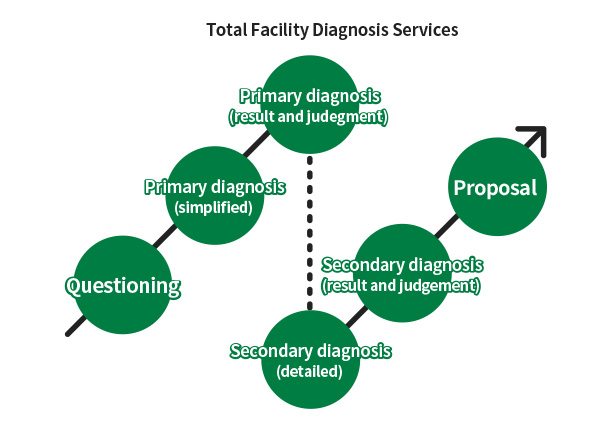

Kinden’s Comprehensive Equipment Diagnostic Program is a “total service program” that offers services from studies and diagnosis to energy conservation proposals for the purpose of maintaining equipment systems at maximum operating capability. The ultimate aim? Letting users operate these systems with complete confidence throughout the equipment’s life cycle.

onservation Diagnosis and Proposals

Energy-saving efforts have become the social mission for corporate activities.

Kinden’s consolidated equipment diagnostic program implements energy-saving and deterioration diagnoses. We aim to optimize energy-saving measures through facility management operations, starting from proposals for renovation, planning, construction and validation.

Examples and suggestions

Air conditioning and sanitation systems equipment diagnosis

Systems performance diagnosis

- Examination and measurement of energy consumption

- Cold water/hot water flow rate measurement

- Duct/outlet flow rate measurement

Systems/equipment deterioration diagnosis

- Heat source equipment performance measurement

- Rotary machinery vibration measurement

- Steam trap functionality studies

Plumbing systems deterioration diagnosis

- Ultrasound wall thickness measurement

- Endoscope studies

- Tube-removing test

Electrical systems equipment diagnosis

Systems/equipment deterioration diagnosis

- Transformer gas-in-oil analysis

- Insulation resistance measurement

- Equipment deterioration studies (protective relays, fluorescent light stabilizers, etc.)

- Heat source quality studies (harmonic measurement, electromagnetic field environment measurement, etc.)

Cable/transmission line deterioration analysis

- Ground resistance measurement

- Current leakage measurement

- Temperature measurement (checking clamping of terminals and joints, etc.)

Renewal Recommendations Based on

Comprehensive Equipment Diagnosis

Facility systems renovations make up an important part of Kinden’s renewal services. Based on the principles of facilities management, these renovations are designed to optimize the performance of equipment and systems according to the life cycle of the facilities they operate in.

Renewal operations are an integral field in Kinden’s total systems support service lineup — from on-site field studies to planning, design, implementation and maintenance — as an integrated systems engineering leader. Operations start with the identification and analysis of the problem areas presented by currently operating facilities based on the results of our comprehensive system diagnosis — including deterioration diagnosis, energy conservation diagnosis and trouble investigation. Our engineering specialists use these results as guidelines in determining the proper corrective measures — using our proprietary systems technology to restore existing systems to maximum operating capabilities and develop new and innovative systems custom-tailored to facility needs.